SILICA SAND – Exploration and Production : Glass Sand

MINISTRY OF ENERGY AND MINERAL RESOURCES Report about Mineral Status and Future Opportunity

SILICA SAND / 2015

Prepared By:

Geo. Marwan Madanat – Geo. Nidal Mehyar – Nihaia A. Zurquiah

Edited By :

Dr. Julia Sahawneh – Geo. Marwan Madanat

CONTENTS

List of Contents

List of Figures

List of Tables

List of Appendices

- Introduction

- Geological Setting

- Location

3.1. Ras En Naqb area

3.2. Qa’ Ed Disa area

3.3. Petra / Ein El Biada area

3.4. Al Jayoshia area

3.5. Wadi Es Siq-Wadi Rakiya area - Mineral Properties

4.1. Chemical Properties

4.2. Mineralogical Properties

4.3. Physical Properties - Reserve

- Background

- Mining, Processing and Industrial Applications

- Mining Companies

8.1. Current markets

8.2. Silica sand prices

8.3. Jordan Market - Investment Opportunities

9.1. Glass industry

9.2. Silicon-based chemicals

9.3. Silica Fume

9.4. Ceramics industry - References

SILICA SAND

1- Introduction

Silica sand is defined as a high purity industrial mineral in which the sand grains are made entirely of quartz. Impurities, if any, are very minor and commonly are clay minerals (kaolinite, illite), titaniferous minerals (rutile, anatase), iron oxides and heavy minerals (zircon, tourmaline). The term silica sand is applied to quartz sand that conforms to the specifications of which the main composition is SiO2 >99%, with very little contaminant oxide contents (i.e., Al2O3, TiO2, CaO, and Fe2O3) and heavy minerals of < 0.1% . And the term glass sand means that silica sand with aspecific size fraction ranges from ( 590) to ( 105) micron.

The range of silica raw materials occurring in nature is extensive and includes relatively pure forms of the mineral such as rock crystal, quartz in the form of unconsolidated sands, and as consolidated rock such as quartzite and sandstone.

Silica is a basic material in the glass industry, ceramic and refractory industries, and the raw material used in making silicon, silicon alloys, silicon carbide, silicones, soluble silicates, and other silicon-based chemicals. Its specialised applications include such products as piezoelectric crystals, optical products, and vitreous silica.

2- Geological Setting

White silica sand deposits are found exposed on the surface, Disi Sandstone Formation of Early Ordovician age and Kurnub sandstone Formation of Lower Cretaceous age which exposed in south of Jordan.

3- Location

3.1. Ras En Naqb Area

Huge silica sand resources of Early Ordovician are found in the area south of the Ras En Naqb escarpment (70km north of Aqaba). The exposures are extended over an area of more than 150km2 with a thickness of about 265-350m.

3.2. Qa’a Ed Disi Area

The area east of Quweira town to the north of Wadi Ram comprises huge reserves of silica sand of Early Ordovician (50km north-east of Aqaba).

3.3. Petra / Ein El Biada Area

White sandstone occurrence of Early Ordovician was found in the area north to Petra town.

3.4. Al Jayoshia Area

A big massive exposure of white, soft friable, and fine sandstone of Lower Cretaceous is located about 6km east-southeast of port of Aqaba. (All locations mentioned above are accessed through the Amman-Aqaba highway).

3.5. Wadi Es Siq-Wadi Rakiya Area

Exposures of good potential for silica sand of Lower Cretaceous white sandstone and belong to the Kurnub Sandstone Group were located in the area between and along Wadi Es Siq and Wadi Rakiyia in Wadi Araba (65km north of Aqaba). These outcrops are fine to very fine-grained sandstone with kaolinite clay as matrix or thin layer intercalations. Geological reserves are estimated of 120Mt.

4. Mineral Properities

4.1. Chemical Properities

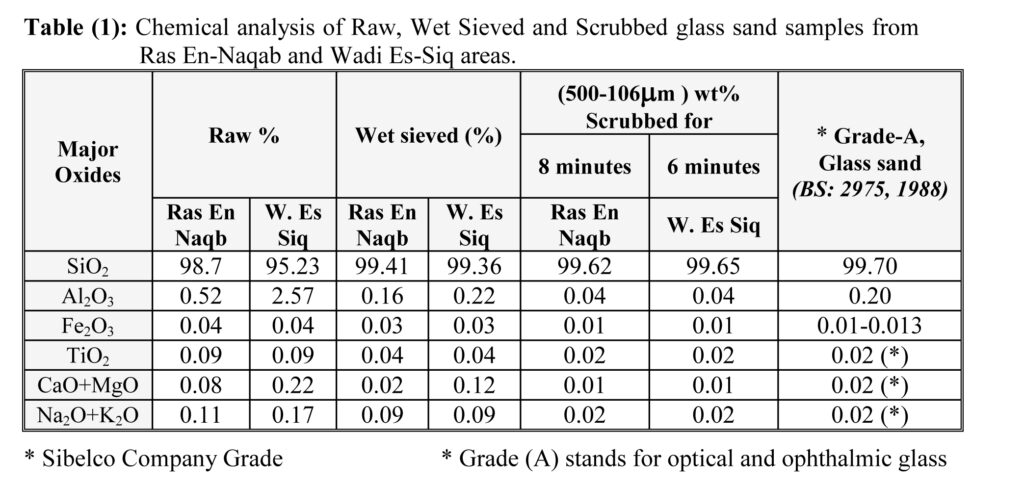

The characterization and beneficiation studies have proved that the four deposits are highly encouraging to produce high quality silica sand.

Table (1)

Chemical analysis of Raw, Wet Sieved and Scrubbed glass sand samples from Ras En-Naqab and Wadi Es-Siq areas.

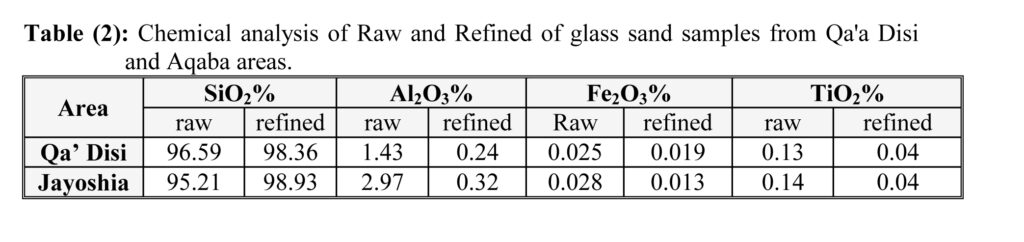

Table (2)

Chemical analysis of Raw and Refined of glass sand samples from Qa’a Disi and Aqaba areas.

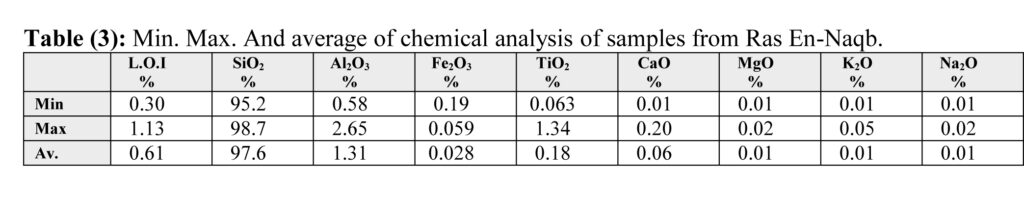

Table (3)

Min. Max. And average of chemical analysis of samples from Ras En-Naqb.

4.2. Mineralogical Properties

Mineralogical investigation of raw sand and glass size fraction indicated that they are consist mainly of quartz as a major mineral with minor a mounts of kaoline, Where as mineralogical investigation of fine fraction (<63 micron) reveals that the fine fractions of the glass sand consist mainly of Kaolin and quartz as amajor minerals with traces of heavy minerals such as rutile, illmenite,… etc.

In year 2000, Geoindustia Company from Czech Republic in their study, found that pure quartz grains are the predominant component of the most promising Jordan glass sand from the Ras En-Naqb deposit, covers of Fe – Oxides occur on the quartz grain surface or cracks locally only. And they found that the heavy minerals content is very low, represented predominantly by Tourmaline, Leukoxene, Zircon and Titanite in fine fraction. The under sieve fraction is formed by Kaolinite and Silica, Silt mainly.

4.3. Physical Properties

Results of partical size distribution analysis showed that the Disi sandstone in the study area is medium to coarse grained. The Glass size Fraction (GSF%) ranges between 68.85% to 81.75%. And the weight percent of the fine particles less than 63 micron ranges between 2.02% to 6.35%.

5. Reserve

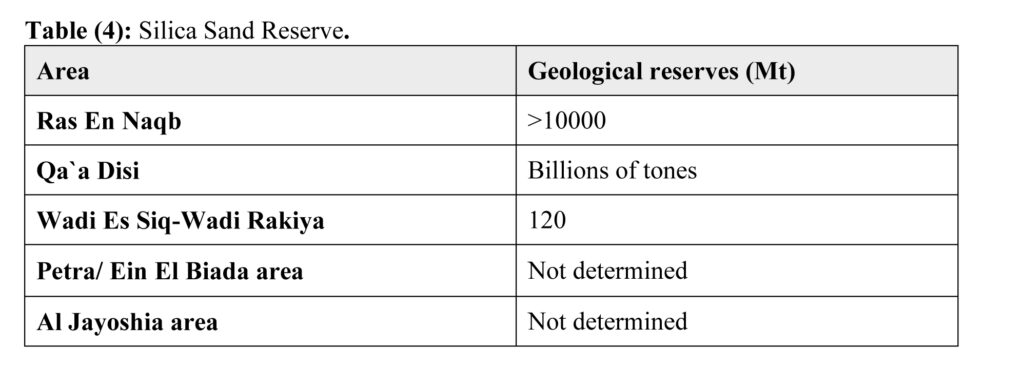

Table (4)

Silica Sand Reserve.

6. Background

Technical studies started in 1970 when Nimry and Haddadin studied the white sandstone outcrops of Ras En Naqb. Swindell Dressler (1974) carried out a study on the properties of these white sands. Hagen et al. (1980) conducted a laboratory investigation on different samples of the silica sand from different localities in south of Jordan. The study concluded that the white sandstone in Ras en Naqb is suitable for glass making. Technostone (1984) investigated the possibility of exploitation of glass sand deposits in the Ras En Naqb area. Barjous (1995) studied silica sand samples of Disi Sandstone formation.

Geological maps at a scale of 1:50,000 covering most of the silica sand outcrops in Ras El Naqb, Qa’ Ed Disi and Wadi Gharandal areas were published by the Natural Resources Authority. Previous mineral exploration and the recent drilling activities carried out by Mineral Exploration Division during the time between 1995 and 1998 have delineated huge reserves in Ras En Naqb area/ south of Jordan (Marawan, Ghassan, and Nidal, 1998).

In year 2000, Geoindustia Company from Czech Republic carried out technological work program including pilot melting tests on silica sand samples from Ras En Naqb area. The tests resulted in manufacturing glassware products such as green and color decoration glassware, luxury lead crystal and barium crystal products.

Alali (2001) conducted a detailed characterization and pilot plant beneficiation study on the silica sand of Ras En Naqb and Wadi Siq-Rakiya/ Wadi Araba. The study proved that high quality glass sand could be produced.

7. Mining, Processing and Industrial Applications

The silica sand are exposed on the surface, almost without overburden, so they are easily mineable by open-pit mining.

Technological work program carried out by Geoindustia Company from Czech Republic, 2000, was terminated by pilot melting tests resulted in manufacturing of glass ware products qualitatively fully comparable with parameters of adequate Czech Republic standards. The pilot melting tests of batches based on the dressed glass sand from Ras En-Naqb deposit (about 700kg.sample) resulted in manufacturing of the following products :-

- Green decoration glassware

- Glassware colouring decoration products

- Luxury Lead crystal products

- Luxury Barium crystal products

The melting pilot program resulted in the high quality of glassware products, including, Lead crystal and Barium crystal as well, and the percentage of Fe2O3 can be decreased to less than 0.018% applying simple dressing process.

From these results it can be concluded that the silica sand can be considerably upgraded through simple beneficiation processes, such as washing and sieving, and can be used in many industrial applications.

8. Mining Companies

There are seven mining companies who have granted mining rights for variable period of time and one for exploration right (one year). Currently, two are producing processed silica flour.

Most of these companies’ products are size classification for sand blasting and construction material with little products for other industrial applications, and now Middle East Regional Development Enterprise Co. (MEREN) start produce different types of silica sand such as, Foundary sand, glass sand, silica flour, construction sand (Fracturing sand and Water filteration sand).

8.1. Current markets

China, Israel, Lebanon, Syria, UAE, Saudi Arabia, Kuwait, Italy.

8.2. Silica sand prices

(Industrial minerals, January, 2006)

Ex-works, UK

Foundry sand, dry, bulk £ 15.50-16.50

Glass sand, flint, container £15-17

Foundry sand, dry, bulk £14.00-25.00

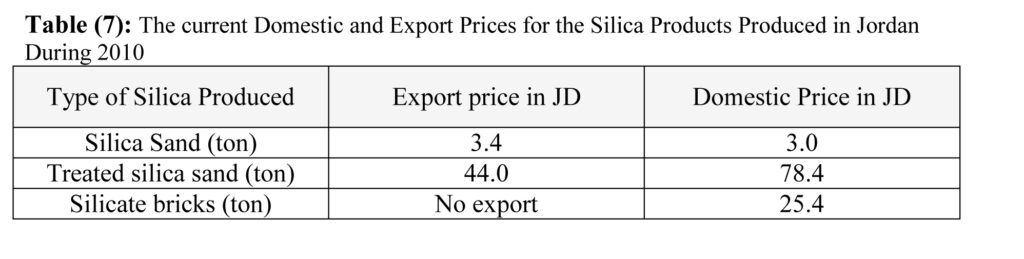

Table (7)

The current Domestic and Export Prices for the Silica Products Produced in Jordan During 2010

8.3. Jordan Market

The local consumption of silica sand around 200,000 mt/year, consumed in White cement, Ceramics, Water filtration and Foundry sand industries. The local consumption figures (30-45,000t) of silica sand mentioned above are not including the consumption in white cement industry.

The glass industry in Jordan started in the early seventies when a glass factory was built 250km south of Amman. Some ten years later, the Boussios and Glaverbel built a modern three-line Pittsburgh plant for Jordan Glass Industries. The plant started operation in 1984 with a gross capacity of 26,000 tpa. There were basic problems with the design and operations, which continued to the end of 1993. The glass manufacturing has been suspended since that waiting for a decision to rebuild or upgrade.

At the moment, there is no glass production in Jordan and usually glass (container, sheets) is imported from the nearby countries such as Saudi Arabia, Syria and Turkey. However, there are some small glass plants for bottles, which are using the cullets (broken pieces) of the remaining glass factory in south of Jordan (Ma’an city).

9. Investment Opportunities

The easy accessibility and mining, close to the harbour, low content of impurities and low content of heavy minerals are advantages for the exploitation of silica sand. Most of the silica sand produced as a raw material and consuimed in the local market with exception few amount for export. There are a lot of quarries in the area of Ras En-Naqb produced silica sand for construction, and two companies produced processed silica sand and silica flour. Deposits are open for investment on the basis of mineral agreement for foreigners investors to produce different types of silica sand, such products should be beneficiated, process and even manufactured in order to be value added to compete prices and to cover transportation cost.

9.1. Glass industry

Glass will be the major issue as no glass production in Jordan since 1994. It should be taken in to consideration that a glass factory should be rebuilt or rehabilitated in an economic and feasible way in order to compete imported glass in quality and price. So it is a good opportunity to produce high quality silica sand for glass industry (Container and sheets) and also for optics and crystals.

9.2. Silicon-based chemicals

- Vitreous silica (Fused silica): Vitreous silica, with purity of at least 99.8% silica, has low thermal expansion, good refractoriness and excellent chemical inertness.

- Silicon Carbide

- Metallurgical-grade Polycrystalline is used in the integrated circuit and solar panel construction.

Ferrosilicon is produced by smelting a mixture of quartz, metallic iron (in the form of steel scrap turning) and a reducing agent such as coke, charcoal, or wood chips.

Silicon metal: Silicon metal is used mainly to form metal alloys, electronic industry, photovoltaic cells and semiconductors, and also in computer chips.

Semiconductor-grade silicon: is used to produce a high purity and single crystal semiconductor-grade silicon, which is used in the electronic industry.

9.3. Silica Fume

Silica fume or microsilica is a by-product of producing silicon metal or ferrosilicon alloys. One of the most beneficial uses for silica fume is in concrete. Due to its chemical and physical properties, it is a very reactive pozzolan. Concrete that contains silica fume can have very high strength and be very durable.

9.4. Ceramics industry

Silica sand is widely used in white ware ceramic formulations, which represents in amount of about 40% of the ceramic body, with exception of bone china in which is not used.

10. References

- Alali, J. 2001. Evaluation and Benefication of Silica Sand and Kaolinitic Sandstone in South of Jordan. Ph.D. Thesis, Nottingham University, U.K.

- Alali, J. 2004. Processing of Silica Sand in Hanout area/ South of Jordan. 8th International Jordanian Geological Conference. Amman, Jordan.

- Barjous, M. 1995. Mineralogy and Processing of Industrial Minerals from Jordan. Ph.D. Thesis Cardif University, U.K.

- Barjous, M. 1997. Mineralogy, Petrography and Upgrading of the Glass Sand from the Southern Part of Jordan. The Second Jordanian Mining Conference, Jordan.

- Department of Statistics, 2001, External trade statistics. Part 2. Amman, Jordan.

- Griffiths, J., 1987, Silica: Is the choice crystal clear? Industrial Minerals. (April), pp. 25-43.

- GIS Geoindustria Report, 2000. Silica sand in: Geological and Technological Evaluation of Selected Mineral Resources in Jordan.

- Hagen, D. and et. al., 1980. Study of Quartz Sandstones of South Jordan to Determine Their Heavy Mineral Content and Their Suitability for Industrial Use. NRA

- Kraishan, S. 1991. Jordan Raw Materials for Glass Making. Ph.D. Thesis.

- Madanat, M., and Mehyar, N. 1999. Evaluation of Ras En Naqb glass sand. Phase 2. NRA.

- Madanat, M., Kailani, Gh. and Mehyar, N. 1998. Evaluation of Ras En Naqb glass sand. Phase 1. NRA.

- Natural Resources Authority, 1998, 1999, 2000, 2001, & 2002, Annual Reports, Amman, Jordan.

- Natural Resources Authority, 1998-2001, Analytical Mining Sector Study in Jordan.

- Nimry, Y. and Haddadin, M. 1970. Glass Sand of Ras En Naqab (Report on Phase 1). NRA.

- Rabba, I. 1991. The Geology of the Qwaiyra Area Map Sheet No. 3049-I. Bulletin No. 16, National Geological Mapping Project, NRA.

- Swindell Dressler Company, 1974 Glass, building material and component industry. Internal Report, NRA, Jordan.

- Technostone, S.P.A. 1984. Final Report on Glass Sand Ras En Naqab Area. Carrara, Rep. Prepared for the Public Mining Co.

“MEREN” is a Jordanian company located in Aqaba , 65km away from Aqaba port with a concession area of 12 square km at Ras Al-Naqab (Al-Humimmah Village).

“MEREN” is a Leading company in extracting silica sand and is considered one of the world’s best-known source for high quality silica sand and quartz, with a minimal negative impact on the environment.

“MEREN Co” is leading the mining of Glassy white and red silica sand of various product specifications up to 99.6% purity and of different particle sizes.

The job is done with solid competence, experience and technical know-how of mining, as processing and development of silica sand in Jordan started since 2007.

Moreover, “MEREN” has a private multi-industry free zone area incorporated with the headquarter in Amman.

Silica plate production

Grinding plant

Ramming Mass